In the realm of outdoor gear, there are few items as versatile and practical as women's camo rubber boots. These boots are designed to provide comfort, durability, and style, making them an essential companion for any outdoor enthusiast.

One of the great things about rain boots with tie is that they come in a variety of styles and colors, making it easy to find the perfect pair to match your personal style. Whether you prefer a classic black rain boot with a subtle tie detail or a bold, bright-colored boot with a statement tie, there are plenty of options available to suit your taste.

One of the primary reasons to pay close attention to your sport shoes supplier is the quality of their products. The sports shoe market has been experiencing rapid technological advancements, with manufacturers constantly innovating to improve comfort, safety, and performance. A reputable supplier will offer shoes that utilize the latest materials and designs, ensuring that athletes receive the best possible support. For instance, lightweight breathable materials that wick moisture away can keep feet dry and comfortable, while specially designed soles can enhance traction and stability during intense activities.

A Heritage of Quality

Navigating slippery surfaces like wet rocks, mossy riverbeds, or muddy banks can be hazardous without proper footwear. Neoprene boots are equipped with sturdy outsoles and aggressive tread patterns that provide reliable traction on various terrains, ensuring you stay stable and sure-footed while fishing. With neoprene boots, you can confidently move around the water's edge, cast your line with precision, and reel in the big one without worrying about slips or falls.

In the wet and cold winter, rain boots are also a great choice with a trench coat and leather coat, both waterproof and warm, but also can be used to concave shape. Under the combination of coat and leather, rain boots can perfectly modify the leg shape, but also increase the layer of wearing, absolutely practical and good-looking.

Ladies snake-proof boots are specifically designed to fit the unique shape of a woman's foot, providing both comfort and protection. These boots are typically made from durable materials such as leather or nylon, with a tough, puncture-resistant sole that can withstand the strike of a snake's fangs. Some boots even come with added features like waterproofing or insulation, making them suitable for all types of weather conditions.

First, consider the type of shoes you're looking for First, consider the type of shoes you're looking for

First, consider the type of shoes you're looking for First, consider the type of shoes you're looking for womens black shoes casual. Do you prefer sneakers, flats, or heels? Each type of shoe has its own unique benefits and drawbacks, so it's important to choose the one that best suits your needs and preferences.

womens black shoes casual. Do you prefer sneakers, flats, or heels? Each type of shoe has its own unique benefits and drawbacks, so it's important to choose the one that best suits your needs and preferences.Insulated Wellington boots are also low-maintenance footwear. Unlike leather boots that require regular cleaning and conditioning, Wellington boots can be easily cleaned with water and mild soap. Their waterproof nature means they won’t easily absorb moisture, minimizing the risk of damp smells and mold. This ease of maintenance ensures that your boots will last longer, providing you with excellent value for your investment.

Moreover, many rubber sole safety boots are constructed with reinforced toes, typically made of steel or composite materials, providing an additional layer of protection against crushing injuries. This feature is especially critical in environments where heavy objects are lifted or moved frequently. Workers can perform their tasks with confidence, knowing that their feet are protected from potential hazards.

Made from high-quality rubber, these boots are built to last, with reinforced toes and heels to protect them from wear and tear Made from high-quality rubber, these boots are built to last, with reinforced toes and heels to protect them from wear and tear

Made from high-quality rubber, these boots are built to last, with reinforced toes and heels to protect them from wear and tear Made from high-quality rubber, these boots are built to last, with reinforced toes and heels to protect them from wear and tear outdoor rubber boots. They're also resistant to oil, gasoline, and other chemicals, making them ideal for use in a variety of outdoor environments.

outdoor rubber boots. They're also resistant to oil, gasoline, and other chemicals, making them ideal for use in a variety of outdoor environments.Comfort and Flexibility

Firstly, they enhance thermal protection, a critical factor in cold water conditions Firstly, they enhance thermal protection, a critical factor in cold water conditions

Firstly, they enhance thermal protection, a critical factor in cold water conditions Firstly, they enhance thermal protection, a critical factor in cold water conditions drysuit overboots. The overboots, when worn with thick insulating socks, can significantly increase the wearer's warmth, preventing hypothermia. Secondly, they provide improved durability, safeguarding the suit's feet from wear and tear. Lastly, they offer better grip and stability, essential for activities that require standing or walking on slippery surfaces.

drysuit overboots. The overboots, when worn with thick insulating socks, can significantly increase the wearer's warmth, preventing hypothermia. Secondly, they provide improved durability, safeguarding the suit's feet from wear and tear. Lastly, they offer better grip and stability, essential for activities that require standing or walking on slippery surfaces.Fishing often means facing a variety of weather conditions, from scorching sun to pouring rain. Neoprene boots are up to the challenge, offering waterproof protection and insulation to keep your feet dry and comfortable in any weather. Whether you're fishing in the heat of summer or the chill of winter, neoprene boots provide the warmth and protection you need to stay out on the water longer and increase your chances of landing that big catch.

Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability

Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability Some feature mesh overlays for enhanced ventilation, while others incorporate leather or synthetic materials for added durability full black sports shoes mens. The choice often depends on personal preference and intended usage.

full black sports shoes mens. The choice often depends on personal preference and intended usage.In conclusion, exclusive sneakers have become a symbol of style, status, and self-expression in the fashion world. The demand for these limited-edition shoes continues to grow, with fans willing to go to great lengths to acquire a coveted pair. Whether you're a seasoned sneaker collector or a casual enthusiast, the allure of exclusive sneakers is undeniable.

Several features make the Górny Podnośnik a preferred choice in lifting solutions

In the realm of contemporary architecture and construction, insulated metal panel (IMP) buildings have emerged as a highly effective solution for a variety of applications. These structures, known for their energy efficiency, durability, and aesthetic appeal, are quickly becoming the preferred choice for many industries, including commercial, industrial, and even residential projects.

Moreover, there is mounting evidence linking long-term exposure to certain metals found in welding fumes to neurological disorders. For instance, manganese, which is prevalent in many welding processes, has been associated with a condition known as manganism—a disorder that resembles Parkinson's disease. Symptoms may include tremors, stiffness, and cognitive decline. This connection emphasizes the importance of monitoring and minimizing exposure to welding fumes, as the implications for workers' health can be profound and far-reaching.

Improved Efficiency and Speed

For industries seeking to remain competitive, the adaptability of these systems is another key advantage. Whether it’s a fully automated spray painting system or a more tailored setup, businesses can customize their solutions to meet specific needs. This flexibility ensures that the equipment remains relevant as production demands evolve.

Experience in deploying these systems reveals that integration into existing production lines is one of the most significant challenges. However, once integrated, the benefits are manifold. Automated systems significantly reduce human error, leading to consistent product quality. The closed-loop control systems adjust parameters in real-time, adapting to changes in environmental conditions such as humidity and temperature, which can affect the viscosity and settling of the coating material.

Conclusion

For larger operations or fixed welding stations, wall mounted fume extractors offer an efficient and space-saving solution to managing welding fumes. These systems can be strategically placed to capture smoke at the source, preventing it from spreading throughout the facility.

Importance in Shipping Operations

For companies considering the shift towards automated systems, the selection process can be daunting. Factors such as the specific requirements of the coating process, the compatibility of materials, and the scale of production must be carefully weighed. Collaborating with suppliers who have a proven track record and offer tailored solutions is crucial in ensuring successful integration and operation.

As industries continue to prioritize worker health and safety, the significance of implementing a Welding Fume Extraction System cannot be overstated. Not only does it protect workers from hazardous exposure, but it also enhances overall productivity and equipment longevity. By investing in such systems, companies not only ensure compliance with health regulations but also foster a safer, more efficient workplace. The future of welding, therefore, lies not only in innovation in welding techniques and technologies but also in creating an environment where workers can thrive without the threat of harmful fumes.

Future Trends

When paired with automated welding arms, wall mounted fume extractors provide consistent airflow and filtration across the workspace. The result is a high-performance welding environment where the automation process can run smoothly without any interruptions caused by environmental hazards. A proper fume extraction system is essential to achieving both high productivity and a clean, safe work environment.

For industries such as automotive, aerospace, and consumer electronics, where aesthetic excellence and functionality are paramount, automatic paint spraying equipment offers an ideal solution. These industry sectors rely on the equipment's capacity to maintain high production volumes without compromising on quality. Moreover, these systems support a wide range of coatings, including water-based, solvent-based, and powder coatings, catering to diverse application needs and environmental considerations.

- Automated Painting Robot Equipped with programmable robotic arms, this robot will execute precise movements to ensure even paint coverage across various surfaces and shapes.

Cost-efficiency is a critical factor in any manufacturing operation, and an automatic spray paint booth offers significant savings in several ways. First, the automated nature of these systems reduces the need for skilled labor, lowering operational costs. Second, the precision of automatic spray painting minimizes paint wastage, cutting down on material expenses.

To make a well-informed decision when considering the purchase of container lifting machines, businesses should conduct a thorough analysis of their specific needs regarding lifting capacity, type of equipment, and budget constraints. It is advisable to obtain quotes from multiple suppliers, compare features, and consider both new and used options. Evaluating the total cost of ownership, including maintenance, fuel consumption, and potential downtime, can lead to more strategic long-term decisions.

- Accessibility Ensure that the fountain is easy for your cat to access. Some fountains may have more complex designs that could deter smaller or older cats.

- Warehousing and Logistics In warehouses, the Górny Podnośnik is frequently used for stacking and unstacking products, improving warehouse operations while enhancing safety for workers handling heavy loads.

5. Environmental Considerations Containers must also comply with environmental regulations, including those regarding hazardous materials. The survey must ensure that containers transporting such cargoes meet specific safety guidelines to prevent pollution and accidents.

Compliance with Safety Standards

Importance of Fume Extraction Systems

Automatic spray coating machines are equipped with advanced technology that allows them to operate with minimal human intervention. These machines utilize systems such as robotic arms or automated spray guns to achieve uniform application of coatings over various surfaces. The key components typically include

Forklifts, especially those designed for container handling, exhibit powerful capabilities, allowing operators to lift and move heavy loads with ease. They are equipped with specialized attachments and sturdy frames engineered to handle the unique weight and shape characteristics of shipping containers. By utilizing forklifts, businesses can significantly increase operational efficiency. This leads to reduced labor costs while promoting a safer working environment.

Yangiliklar va Rivojlanish

This enhancement in efficiency leads to faster production cycles, allowing companies to meet increasing demands without compromising on quality. As consumers expect quick delivery times and higher standards, the need for speed in production has never been more critical. Automatic systems meet this demand by ensuring that every piece of equipment is working optimally to deliver results rapidly.

In the world of modern manufacturing, precision and adaptability are key to achieving high-quality results. The advent of automatic paint spray machines has revolutionized how industries handle diverse coating applications. These machines are not only efficient but also versatile, offering tailored solutions for various industrial needs. From the intricacies of small-scale projects to large-scale production, automatic paint sprayer machines deliver consistent performance.

Understanding the Exhaust Arm in Welding Applications

From an SEO perspective, companies looking to enhance their digital presence should focus on producing content that highlights real-world case studies, efficiency metrics, and long-term cost-benefit analyses of automated spray coating systems. Bringing these systems to life with clear examples and testimonials from industry leaders can significantly enhance search visibility and authority on this subject.

In addition to health benefits, portable weld fume extractors can also help businesses comply with safety regulations and standards. Occupational Safety and Health Administration (OSHA) and other regulatory bodies enforce strict guidelines regarding acceptable air quality levels in workplaces. By integrating these portable extractors, companies can ensure compliance with these regulations, reducing the risk of penalties or legal issues.

Trustworthiness in automatic spray painting machines is also reinforced through stringent testing and quality certifications. Many machines are subjected to rigorous examinations to meet international safety and performance standards. This authoritative validation not only enhances the credibility of the device but also assures consumers of its reliability and safety in demanding industrial environments.

In the ever-evolving world of logistics and transport, the role of heavy-duty vehicles, particularly Lori Angkat Kontena (container lifting trucks), has become fundamentally important. These specialized trucks are designed to transport shipping containers efficiently and safely, serving as a vital link in the global supply chain. With the rise of e-commerce and international trade, understanding the impact and functionality of Lori Angkat Kontena has never been more crucial.

Compliance with Safety Standards

Importance of Exhaust Arms in Welding

Trustworthiness is paramount when integrating automated systems into critical operational facets. Manufacturers must rely on systems that have been rigorously tested under various operational conditions. Reputable suppliers provide extensive documentation, from compliance with international standards to validation reports demonstrating reliability and durability. Case studies often accompany these documents, showcasing the systems' successful deployment in similar industrial settings.

There are several types of ventilation systems that can be employed in robotic welding environments

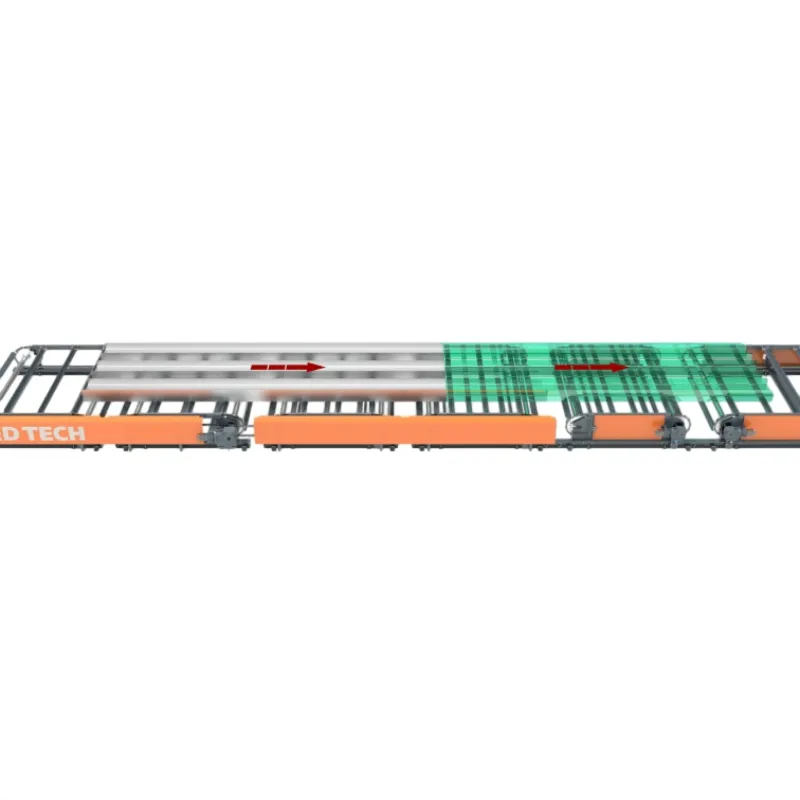

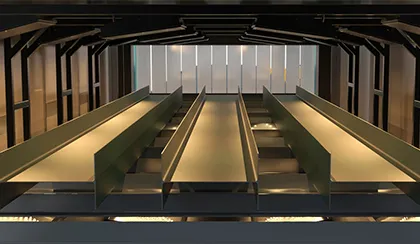

. Each system has its advantages and is suited to different application needs.A container loading platform refers to a dock or an area specifically designed for the loading and unloading of shipping containers. These platforms can be found in various facilities, including ports, freight terminals, and warehouses. The design of these platforms prioritizes safety, efficiency, and the careful handling of cargo. They are equipped with various tools and machinery, such as cranes, conveyor belts, and forklifts, which assist in moving containers seamlessly.

Safety remains a paramount concern in welding, and portable welding units are designed with safety features to protect users from potential hazards. Features such as thermal overload protection, automatic shut-off, and built-in ventilation systems help mitigate risks and ensure a safe working environment, whether on a construction site or a DIY project at home.

Elevation Markings on ISO Containers